Please click on the below link to read this article in Hindi:

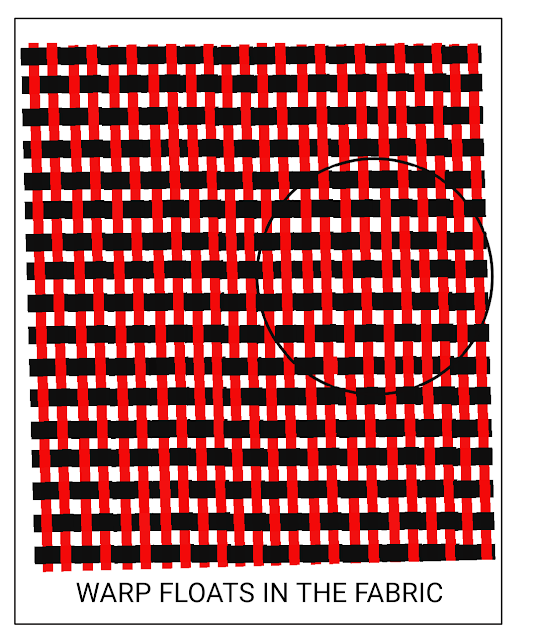

WARP FLOATS IN THE FABRIC:

"The unwoven warp ends on the fabric surface at any particular place is called warp float". This is very common fabric defect. There may be single warp end in the fabric which has been left to weave in the fabric. There also may be many number of warp end left to weave in the fabric. The unwoven end may be missed out to weave for one pick. The ends may be also missed out to weave for many picks too. This defect gets much serious when the frequency of defect gets high. See the below graphic .

There are several reasons which help to generate warp floats in the fabric. Since we know that shed formation takes place by raising and lowering of ends according to peg plan. When any end fails to raise or lower during shed formation , the end gets left unwoven with the pick. In this way, warp floats are generated in the fabric.

The main possible reasons for warp floats are given below:

The main possible reasons for warp floats are given below:

Warp tension:

The warp tension has great importance during weaving. If the technician doesn't select proper warp tension, or keeps low warp tension to reduce warp breakage, the chances of warp floats gets increased. The warp ends fail to raise completely and weft yarn passes over the warp ends. Thus the warp tension plays very important role in warp floats. The technician should choose an amount of warp tension in such a way that there is lowest warp breakage rate and there is not a warp floats problem in the fabric.

The warp tension has great importance during weaving. If the technician doesn't select proper warp tension, or keeps low warp tension to reduce warp breakage, the chances of warp floats gets increased. The warp ends fail to raise completely and weft yarn passes over the warp ends. Thus the warp tension plays very important role in warp floats. The technician should choose an amount of warp tension in such a way that there is lowest warp breakage rate and there is not a warp floats problem in the fabric.

Quality of warp beam:

The quantity of warp beam directly influences the frequency of warp floats. If the beam winding density near the flanges is lower then the middle ends, then weaving technician comes into big trouble. When he applies required warp tension, he fails to achieve uniform warp tension on the loom. The warp tension gets lowered at both the selvedge. This warp tension variation causes warp floats near the selvedge in the fabric. A high degree of care should be taken to avoid the variation in beam winding density.

The quantity of warp beam directly influences the frequency of warp floats. If the beam winding density near the flanges is lower then the middle ends, then weaving technician comes into big trouble. When he applies required warp tension, he fails to achieve uniform warp tension on the loom. The warp tension gets lowered at both the selvedge. This warp tension variation causes warp floats near the selvedge in the fabric. A high degree of care should be taken to avoid the variation in beam winding density.

If the frequency of short end is very high in the Weaver's beam, it also generates warp floats in the fabric. Weaver keeps manual watch over the short ends coming from Weaver's beam. If he gets failed to see the coming short end from the warp beam, the coming end pass through drop pin and Heald wire. Now, these ends are entangled to adjacent end and prevent the raising and lowering of ends. Thus these short ends cause warp floats in the fabric. There should be minimum short ends in the beam.

Yarn quality:

The yarn quality is always a very big issue in weaving. It is directly associated with warp floats problem in the woven fabric. Big knot always results in the form of warp floats in weaving. A big knot prevents the up and down movement of adjacent end. In this way the big knot creates warp floats in weaving. A Weaver should always use auto spliced yarn to avoid these warp floats. We should always use Weaver's knot during warping and weaving.

The yarn quality is always a very big issue in weaving. It is directly associated with warp floats problem in the woven fabric. Big knot always results in the form of warp floats in weaving. A big knot prevents the up and down movement of adjacent end. In this way the big knot creates warp floats in weaving. A Weaver should always use auto spliced yarn to avoid these warp floats. We should always use Weaver's knot during warping and weaving.

Yarn cleanliness:

it is very important aspect. The environment of spinning department should be as clean as possible. If fibers are flying in the department, they get spun with yarn to be spun on machine. When this yarn goes to weaving, the wrapped flying fibers with the yarn fail to pass through the dent of the reed. These flying fibers converted into ball form behind the reed. These flying fibers balls interrupt the raising and lowering movement of adjacent end. Thus these balls results in the form of warp floats in the fabric.

it is very important aspect. The environment of spinning department should be as clean as possible. If fibers are flying in the department, they get spun with yarn to be spun on machine. When this yarn goes to weaving, the wrapped flying fibers with the yarn fail to pass through the dent of the reed. These flying fibers converted into ball form behind the reed. These flying fibers balls interrupt the raising and lowering movement of adjacent end. Thus these balls results in the form of warp floats in the fabric.

Hairiness of the yarn has great impact on the frequency of warp floats. If yarn has much hairiness in it, it creates the probability of fusion of two adjacent ends. The two ends fusion interrupts the up and down movement of ends. This interruption results in the form of warp floats in the fabric. The fusion of two warp ends due to much hairiness creates the probability of failure of warp break stop motion. This stop motion failure allows the loom to run continuously with broken end. This broken end gets entangled with adjacent end and prevents up and down movement of the ends. In this way the warp floats are appeared in the woven fabric.

Size percentage:

If the sizing of warp yarn is not proper, it may be the reason of warp floats in the fabric . Since we know that warp ends are rubbed to each other during shed crossing during weaving. If the beam is not sized properly or size percentage is not sufficient, then fiber fraying gets started in the yarn. This fraying of fibers helps into yarn fusion and generates warp floats in the fabric.

If the sizing of warp yarn is not proper, it may be the reason of warp floats in the fabric . Since we know that warp ends are rubbed to each other during shed crossing during weaving. If the beam is not sized properly or size percentage is not sufficient, then fiber fraying gets started in the yarn. This fraying of fibers helps into yarn fusion and generates warp floats in the fabric.

Loom settings:

if the all above stated terms are ok, then the role of loom settings comes into play.

if the all above stated terms are ok, then the role of loom settings comes into play.

The setting of Heald shafts height should be done as per the instruction of setting manual provide by loom manufacturer.

Shed crossing timing should be proper. You may keep it slightly early. It helps to avoid warp floats problem.

The distance between drop pin stand and last Heald shaft should be as minimum as possible to reduce the probability of ends fusion.

The environment of loom department should be neat and clean. It reduces the chances of wrapping of flying fibers with the yarn.

The trenches of return air of humidification must be cleaned after a regular time of interval.

Loom should be cleaned with compressed air twice in a shift of 8 hrs.

For further improvement in working environment if weaving department, overhead cleaner should be used.

You may also be interested in following articles

Objectives of calendaring process, types of calendars, structure and working principle of calendaring machine

TYPES OF YARN, CLASSIFICATION OF YARN

Structure and working principle of water-jet loom weft insertion system

Related articles:

Objectives of calendaring process, types of calendars, structure and working principle of calendaring machine

Objectives of singeing, types of singeing machines, structure and working principle of singeing machines

PRE - TREATMENT PROCESS OF NATURAL CELLULOSIC FABRICS OR FABRIC PREPARATION FOR DYEING

CHEMICAL COMPOSITION OF COTTON FIBRE, CHEMICAL FORMULA OF COTTON FIBRE, CROSS SECTIONAL VIEW OF THE COTTON FIBRE

Definition of a stitch in knitting process and different type of stitches in weft knitting process

Differences between weft knitting and warp knitting process

Different types of fancy yarns

TYPES OF YARN, CLASSIFICATION OF YARN

GENERAL TERMS TO BE USED IN TEXTILE

HOW TO FIND YARN COUNT FOR GIVEN FABRIC GSM:

SCHEMATIC DIAGRAM OF LOOM

FABRIC ANALYSIS

CLOTHE OR FABRIC COVER FACTOR CALCULATION

Verdol Jacquard or fine pitch Jacquard shedding mechanism

Double-lift and double-cylinder jacquard shedding mechanism

You may also be interested in the below-sponsored links:

Structure and working principle of water-jet loom weft insertion system

Types of rapier weft transfer process, Negative weft transfer and positive weft transfer

Rapier weft insertion system l Types of rapier looms l Weft yarn passage and working principle of rapier weft insertion system

An introduction about shuttleless weaving ( a non conventional weft insertion system)

Parallel picking or parallel weft insertion systems

Structure and working principle of water-jet loom weft insertion system

Structure and working principle of projectile loom weft insertion system

Types of rapier weft transfer process, Negative weft transfer and positive weft transfer

Rapier weft insertion system l Types of rapier looms l Weft yarn passage and working principle of rapier weft insertion system

An introduction about shuttleless weaving ( a non conventional weft insertion system)

Parallel picking or parallel weft insertion systems

Structure and working principle of water-jet loom weft insertion system

Structure and working principle of projectile loom weft insertion system

No comments:

Post a Comment